——Realize the intelligent - continuous - high - efficiency of enterprise production——

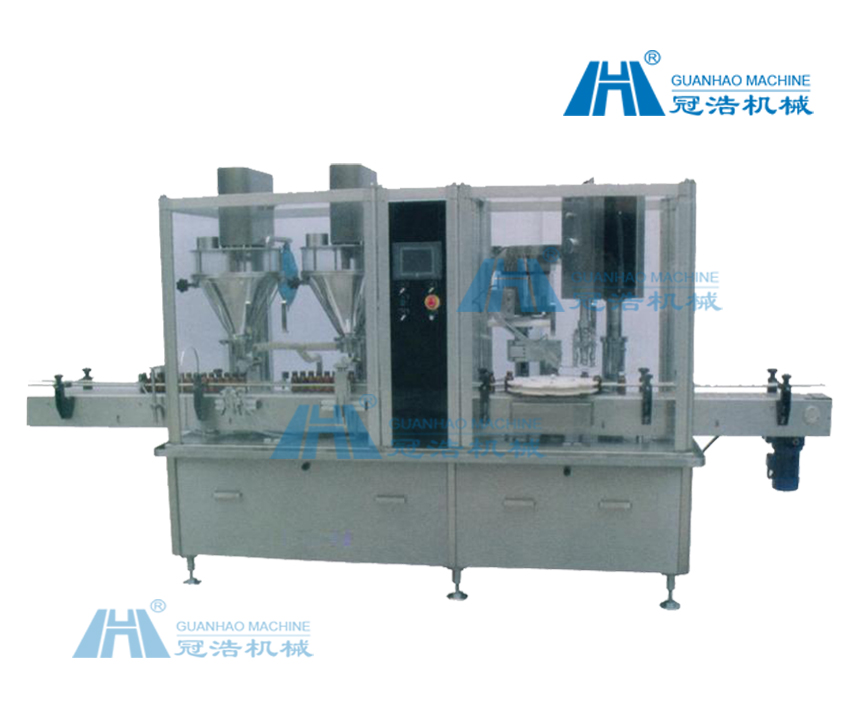

Automatic powder filling machine

Product Model: GH-F2A

Introduction:

1.The whole machine made of stainless steel,especially suitable for GMP certification,food hygiene certification required anti-corrosion chemical products packaging.

5. Material proportion detect functionon:overcome the shortcomings of the resulting weight change due to changes in the material proportion .

6.The air resistance of glass hermetically sealed stainless steel side open the composite hopper, See clearly material at a glance, the powder isn’t allowed escape outside,filling export equipe with dust absorption device to protect the manufacture room enviroment.

7.Replace the screw attachment, be able to adapt to a variety of materials for ultra-fine powder to large particles.

Technical parameters

1 Metering mode:spiral rotation quantitative formula(applicable to small particles or powder canned)

2.Container size: cylindrical container φ20-100mm 50-200mm higher

3.Packaging weight :10-500g (transform screw attachment)

4.Packing precision: Package weight ≤ 100g deviation ≤ ± 1g 100g deviation ≤ ± 1%

5.Packing speed :20-60 cans/min

6.Power supply: three-phase 380V (or custom single-phase 220V) 50-60Hz Total power: 1Kw

7.The whole weight: 200Kg

8.The whole volume: 2440 × 680 × 1770mm

9.Hopper volume: 26L

Can be customized according to customer requirements

|

充填容量 |

3-500ml(via changing screw rods) |

|

充填头数量 |

2 Sets |

|

生产速度 |

30-60 B/min |

|

灌装精度 |

0.75% |

|

料箱容积 |

30L×2 |

|

压缩空气 |

5-6Kg/cm 0.2m3/min |

|

电源 |

3P 380V/220V 50-60Hz 2500W |

|

体积(L×W×H) |

2400×1100×1800mm |

|

净重 |

750Kg |

|

充填容量 |

3-500ml(via changing screw rods) |

|

充填头数量 |

2 Sets |

|

生产速度 |

30-60 B/min |

|

灌装精度 |

0.75% |

|

料箱容积 |

30L×2 |

|

压缩空气 |

5-6Kg/cm 0.2m3/min |

|

电源 |

3P 380V/220V 50-60Hz 2500W |

|

体积(L×W×H) |

2400×1100×1800mm |

|

净重 |

750Kg |

全自动100克颗粒粉剂灌装机

原理特点

A、该机是集机、电、光、仪于一体,PLC控制, 具有自动定量、自动充填、自动调整计量误差等功能

B、速度快:采用螺旋下料、光控技术

C、精度高:采用步进电机及电子称量技术

D、包装范围宽:同一台定量包装机在10-1000g内通过电子 秤键盘调整及更换不同规格的下料螺旋连续可调

E、适用范围广:粉剂状、颗粒状物料均可

F、适合罐类、瓶类等各种包装容器粉剂定量包装

G、因物料比重和料位变化造成的误差可自动进行跟踪修正

H、光电开关控制,仅需人工把瓶摆放在输送机上,瓶子到灌装嘴时自动汽缸挡瓶,自动灌装。

I、与物料接触部位均采用不锈钢制作,清洗方便,防止交叉污染

J、可配置供料装置,更方便用户使用

技术参数

电源: AC380V

功率: 900W

包装精度:±1%

包装规格:10g-1000g

包装速度:800-1500瓶

总重量:380kg

整机尺寸:长*宽*高=2500*650*2000(mm)

可根据客户要求订做