Sticker labeling machine in recent years is the most common type of labeling machine, the technology also is the rapid increase. On the drug production enterprises, both from the labeling product ion equipment, or from the label to be affixed to the body with itself, will raise higher requirements.

Now facing the domestic motley crowd self-adhesive labeling machine market, pharmaceutical production enterprises how to choose more cost-effective sticker labeling machine will be of concern. This article from the main function and control, label conveying speed, printing speed and yield, special purpose, labeling quality four respects discussed sticker labeling machine choice points.

Overview of domestic and international labeling machine, its working principle are similar, is to label peeling transfer plus rolling affixed together, but in the control and manufacturing is not the same.

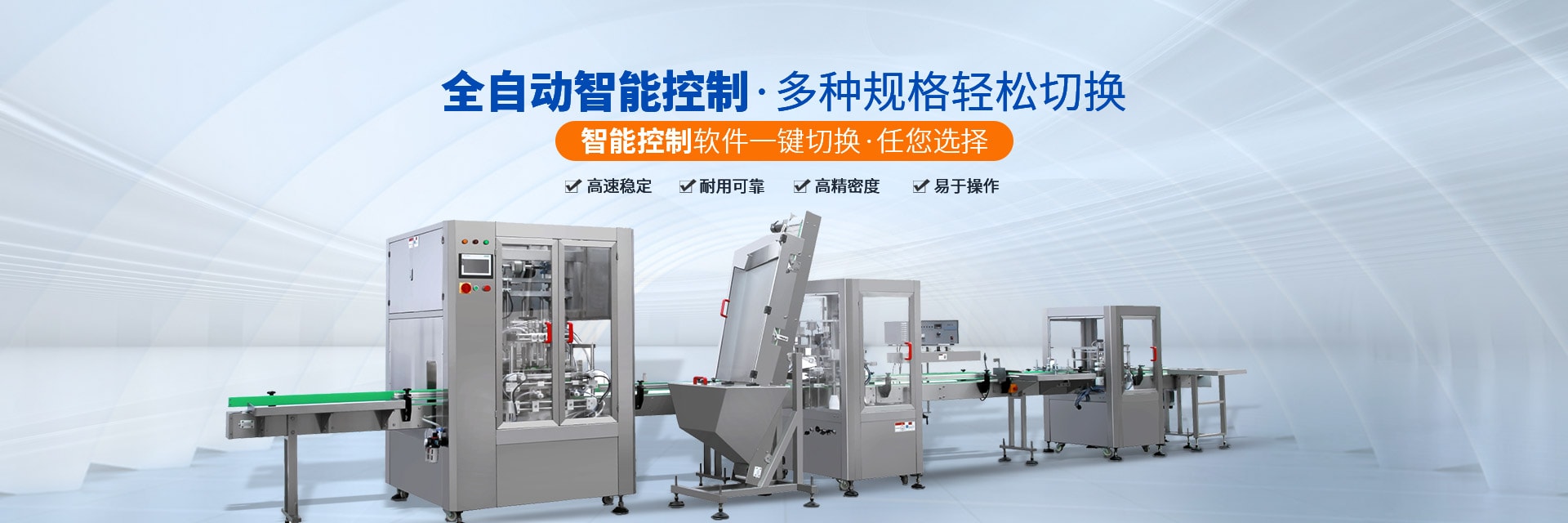

General labeling machine by the label body, roller sticking mechanism, hot printing mechanism, conveying mechanism, a transmission mechanism, and a control system. Among them, rolling and sticking mechanism is divided into suitable for flat bottles roller rolling stick style and suitable for round bottle rolling stick seat roller sticking ways. At the same time, sticker labeling machine according to the bottle vertical, horizontal state; according to send mark rate low, medium, high speed; according to the labeled container characteristic round bottle,bottle, bottle, long bottles ( shaped bottles in pharmaceutical industry; less ) according to requirements of one-side veneer, double-sided; according to the label characteristics of general label, transparent label.

1、from the main function and control on Selection The last sticker labeling machine labeling was detected in body front is photosensitive, due to the different diameter of the bottle for the corresponding eye movement or labeling time changed, if not for this change cannot ensure labeling in each bottle at the desired location. Now the products are with " automatically calculates the length of label " function, this function can effectively make up the weakness of. " Automatically calculates the length of label " in the PLC and servo motor technology is formed on the automatic control technology, when the conveying belt by detecting the electric bottle, bottle was measured the radius, and the bottle body round edge on the bump as labeling signal induction, i.e. whether the bottle diameter are small, the outer circle of the bottle on the edge of the projecting point for labeling the inductive signals, so the distance between eyes and a stripping plate without mechanical adjustments, mark time also does not need to make another adjustment, this is " automatically calculates the length of label " principle of automatic control. It is also on the labeling machine is due functional preferred point.

In the control of speed synchronization, sticker labeling machine should take the " automatically calculates the length of label " function, should also complete automatic conveyor belt speed, speed, mark mark length synchronous adjustment, it is also associated with the traditional adhesive labeling machine of the distinction, is the guarantee quality stability of labeling. Traditional sticker labeling machine speed control is to rely on personal experience and make adjustments, and artificial adjustment difficulties are all actions to synchronization. If not synchronized, the labeling process is frequently changed, resulting in poor quality of labeling.

In the control system, the preferred ( PLC+ man-machine interface ) of the main control system, in contrast to earlier single chip computer (SBC), using a generic type PLC for the control device, can make PLC control system to achieve the following purposes:

(1)more stable, and more reliable;

(2) after the maintenance more convenient, more upgrades simple;

(3)can be conveniently and on line control station.

In addition, also considering the increase of the visual system, it can print integrity, characters, and labeling after the label is whether complete, whether real-time detection, control and alarm.

2, from the label conveying speed, printing speed and yield of choice

In the choice of adhesive labeling machine, people tend to focus on the labeling yield ( i.e. how many pieces per minute can paste ), and could not comprehensively from label conveying speed, printing speed, roller affixed to synchronize with speed.

Of course, the labeling yield covers other indicators, but other speed indicator on the use of quality and production play a key role in the development, people from the analysis of the mechanism on the merits and potential initiative, which is the choice of adhesive labeling machine should be comprehensive survey.

(1)self-adhesive labeling machine to send the standard speed, now people in supporting the sticker labeling machine output, not according to the width of label and printing speed of confirmation, with manufacturers in the sample maximum yield index selection is not reasonable, because the general manufacturers sample gives the highest yield index is a a length of label and a method for printing on the basis of the. Therefore, in the labeling yield selection should first investigate the label conveying speed, from theoretic give mark speed and labeling yield relationship : Q=1000V/ ( L+a )

Among them: Q for maximum speed to send the calculated maximum labeling yield, /; V is the largestlabel conveying speed, m/min; L mm; a single tag length, spacing between label, mm.

For example, on a diameterφ 36 bottle labeling, L=52mm, a=3mm, V=25m/min, Q=454 / branch. When you select V=25m/min, considering other factors, label length L=52mm, Max labeling yield only in 400 / range, not taking into account the speed or replacement after longer label.

The domestic market, general labeling machine self-adhesive products the largest label conveying speed is 38m/min, which has the technical strength of the company to product the biggest label conveying speed is set to 70m/min, this index can explain :

to ensure that the original labeling yield condition, the rotor pump can be adapted to tag length transform ( longer ); high speed feeding standard is established in the mechanical hardware quality, element configuration and servo control technology, is not generally manufacturers to make, its value is reflected by the manufacturers of professional and technical standards.

(2)labeling machine self-adhesive printing speed of the pharmaceutical industry, the labeling machine, label printing is particularly important in batches. Therefore, in the labeling machine to send paste and rolling posted speed selection,but also consider the printer printing speed, the minimum count as actual labeling production ability value.

Label printed on the batch in the pharmaceutical industry in general to hot printing, hot printing is to heat the prefix by ribbon print text technology. Why hot printing self-adhesive label printing number is the pharmaceutical industry preferred? Hot printing and new inkjet printing methods, one is hot printing production cost and low maintenance cost of the device; the two is the hot printing does not occur in similar parts of ink jet printing apparatus, printing solvent odorous will affect the air-conditioning system circulating; three is the ribbon can be recovered, with environmental protection.

Although, hot printing has its characteristics, but it also has weakness, is its printing speed has a certain limit, the domestic hot printing machine the fastest speed in the 400 general BPM, after this value to print out the text is not clear. So some people think: with hot printing self-adhesive labeling machine can only be set for maximum yield of 400 / cent, more than 500 pieces / yield self-adhesive labeling machine with ink jet printing.

3, from the perspective of choice for special purposes In the labeling, often encounter the problems of special purpose, pharmaceutical production, may be encountered:

(1) the double-sided;

(2) a similar plastic bottle surfaces due to release agent label adhesion caused decline or generate surface has " bubble " phenomenon.The labeling machine is presented for the selection of more special requirements.

3.1, on the double-sided options should be considered in terms of

If you need to flat bottles, bottles, bottles are double-sided, should at least consider the following points:

(1) the label head can realize the multi-dimensional space adjustment, to ensure that the labeling accuracy, such as 6 dimensional adjustment;

(2) the label head adopts a double roller design, to enhance tag tension, Eli and long tag tag.

3.2, labeling surface easy to produce " bubble " problem consideration

(1)should eliminate electrostatic effects, can be used to electrostatic ion fan bottle body for electrostatic treatment, at the same time using electrostatic brush to remove the label electrostatic;

(2) increase the label labeling pressure, as much as possible to increase adhesion between the label and bottle;

(3)the labeling process, it is possible for the label and bottle into line contact, to completely off " bubble ".

4, from the labeling quality about choosing

The generally accepted labeling quality requirements are:

(1)labeling error less than ±1mm, even if the back repeatedly labeling coincidence position also can achieve this value;

(2) paste label and bottle surface should be attached, should be flat, no wrinkles, no " bubble " phenomenon;

(3) print a batch number writing clearly discernible, without overlapping and fuzzy phenomenon, and the batch number and position error of less than ±1mm.

In order to realize the labeling requirements, in addition to the label quality and reasonable operation, also associated with the device, so the selection should consider the following points:

(1)labeling smoothness, mainly to see the rolling and sticking mechanism for the rational design and processing of high precision in the rolling stick, under pressure to ensure that the label and the surface of the bottle body line contact;

(2)the drive element high requirements, because standard action is the core of 1 sets of high precision low inertia servo motor, to ensure that the quality of labeling, the application of system closed loop control, at the same time the motor itself can always in the correction of their own position to conduct their own compensation;

(3)detection methods and detection element, but also to ensure the quality of labeling and labeling production base, has the technical strength of the producers changed the past detecting element detects only label printing the not perfect place, now the detection to thickness, the use of labels and label the gap between the thickness change to control servo motor running, this is the best mode of detection, this reliability more;

(4)to achieve the perfect labeling words, the whole control is very critical, especially bottle conveying speed and feed speed of mark. In the choice of control should pay attention to, production speed signals can be sent to the synchronous system, and through analysis and calculation to the servo motor, the two running speed matching requirements;

(5)element configuration, because of the high speed labeling is based on the machine running, the requirements of each component to respond quickly, all actions are in instantaneously, the detecting element configuration also request. For example, on the labeling, labeling motor drive servo motor, motor, belt conveyor delivery motor, motor, inverter, separation labeling lash, labeling was detected in eye, delivery stop proximity switch, programmable controller, man-machine interface element has a configuration requirements.

In 5, the label and print settings

In 5.1, the label of choice

Sticker labeling machine used to label are rolled, the label quality will directly affect the labeling quality, label printing process of cutting, slitting, electrostatic and dust processing is more important.