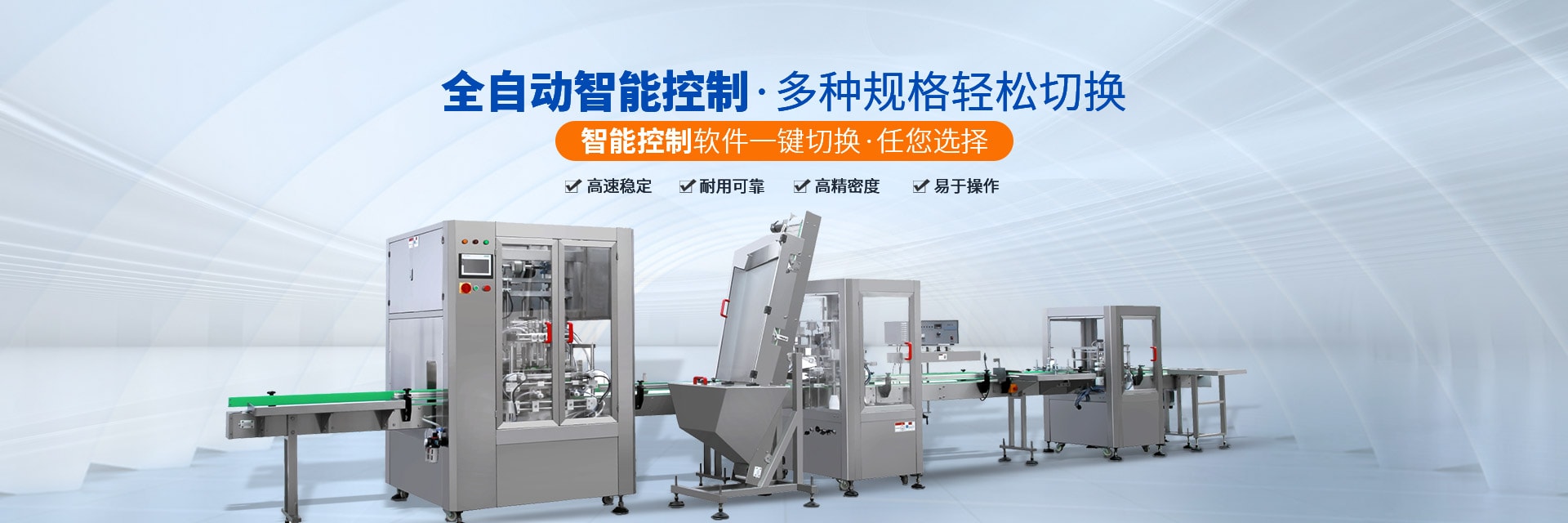

——Realize the intelligent - continuous - high - efficiency of enterprise production——

A2 semi-automatic filling packing machine is mainly composed of host, electrical distribution box filling of PLC, touch screen and electronic scale. The filling packing function complete measuring, filling, etc. The machine all stainless steel, corrosion resistance; PLC touch screen man-machine interface, display in both Chinese and English, the operation is convenient intuitive; Conform to the state "QS" and "GMP" certification requirements; Filling adopts servo motor drive, mixing use Taiwan maintenance-free gear motor, stable performance, high precision packaging; Fully sealed, stainless steel and organic glass container combination, easy unpick and wash. The workbench convenient lift; Using special screw filling, computer real-time tracking, it has high speed and precision; All kinds of packaging parameters can be stored, can store up to 10 formula; For larger dust material packaging, can be added with dust collection system, clean workshop environment; By changing the screw attachment can adapt to milk powder, monosodium glutamate, solid drink, white sugar, glucose, coffee, medicine, pesticide, solid powder, granular additive, dyestuff, veterinary medicine and other packaging specifications for packing powder/granule.

Can be order customized for according to your requirements.

2、Technical parameters:

|

model number |

GX—LA2 |

|

filling type |

Weighing feedback tracking screw rotary type |

|

Filling weight |

1—500g(change screw component) |

|

filling accuracy |

packingweight≤100g

deviation≤±0.5-1g |

|

packing speed |

20—50bag/min |

|

Tank volume |

30 L |

|

voltage |

3 phase 380V(or customize1 phase 220V) 50/60Hz |

|

power |

1 KW |

|

weight |

230kg |

|

dimension |

800×750×1900mm |

Capping machine

Automatic cap sending technical parameter:

Diameter of bottle: 30-80mm

diameter of cap:singleness cap(different cap need to change distributor)

cap sending speed: 20-40 pcs/min

distributor power:350W

screw capping technical parameter:

diameter of bottle: 30-80mm

diameter of cap: 18-50mm

capacity:20-40 pcs/min

screw capping motor: 550W

conveyor: 82mm, 1.7m stainless steel 304 chain

drive motor: 90W frequency adjust

three forms induction aluminum foil sealing machine

technical parameter:

applicable scope of bottle diameter:6~55(mm)

applicable of bottle height: 40~200(mm)

production capacity: 260 bottle/min (for example bottle :diameter of40mm)

conveyor: L 1700 MM W 82 MM

conveyor speed: 0~13.5m/min

voltage: 220V/50Hz

power: 3000W

external dimension: 1700×410×1350 (mm) (L×W×H)

total weight: 100Kg

Vertical round bottle labeling machine

technical parameter:

labeling accuracy: ±1.0mm

applicable scope of label: square label:H 10~100 (mm) L 10~300(mm)

round label:diameter:10-100 (mm)

applicable scope of product: round product:diameter :20-90 (mm)H 15-300(mm)

production capacity:100~150bottle/min

voltage:220V/50Hz

power:300W

external dimension:1710×950×300(mm)(L×W×H)

total weight:146Kg

KN500K small character inkjet machine

As in 2009, the latest model, kenuo hua Matthews KN500K spurt the inkjet printing machine integration with the international latest technology, made a breakthrough in multiple technologies. Adopted in today's popular 320 * 240 LCD screen, can be directly inserted into various special symbols on the screen, edit graphics, very easily by various lattice screen input and text information, its stability and reliability can be satisfied with all kinds of production and processing enterprises for a long time continuous work, to ensure production and stable operation.

Safe, stable, reliable operation Nozzle,

automatic cleaning, automatic ink wash

1 key switch machine control, an instant Stable operation,

can be in high altitude area

320 * 240 LCD screen display Convenient,

multiple working status record query

Multiple automatic detection fault early warning alarm function

Functional features: Automatic ink road system

Article 900 data information storage/output

320 x 240 LCD screen display,

English, Chinese, location input method

Print information can store, call at any time Graphics editor, screen interface easily

A key switch machine design, equipped with this password, safe and reliable,

in English and Japanese characters, Numbers (Arabic numerals, Roman numerals) and special symbols

Spray print function Spray publishing count: 1-2 rows (KN2120), 1-3 lines (KN2130)

Top spray printing speed: up to 1076 characters per second (7 х 5 single line)

A variety of fonts/language/logo/character spray print Timing, counting, spray print, print the information can be positive sequence, reverse, reverse, reverse direction four spray printing Count, batch number, automatic display products, the information delay spray print Spray printing height: 7 х 5 single row: 1.8 -5 mm, 16 х 16 single row:5-15 mm

Up to 9 times, bold coefficient Font bitmap:

KN2120: 7х5、10х7、12х12、16х10、16х16

KN2130: 7х5、7х7、10х7、12х12、16х10、16х16、24х8

Supplies and accessories

Ink: black, blue, red, green, UV ink (stealth)

Thinner: special thinner kenuohua Matthews

Accessories: optical fiber sensor, the nozzle stents

To choose accessories: hand-held spray printing rack, paging machine, meter, conveyor belt, etc

Production line can be customized according to customer requirements.