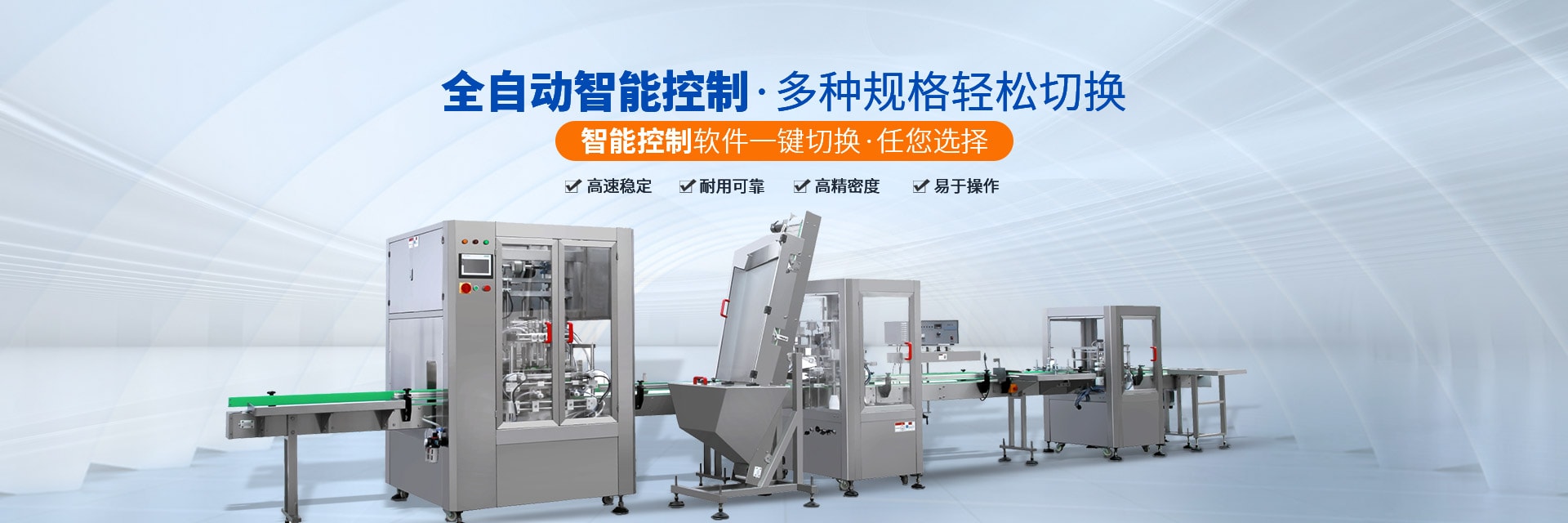

——Realize the intelligent - continuous - high - efficiency of enterprise production——

Introduction:

1.This equipment used PLC micro-computer software control system, which has powerful memory function, and able to pre-setting 50 group of labeling parameters.

2.It is simple and quick operation. The label controlled by mutual inductance stepper motor.

It ensures that the speed of sending label

is sames as the imported inverter, to ensure that the machine's stability and reliability.

3.Stainless steel frame construction and components are standard;

4.Labeling speed is automatically synchronized with conveyor speed to ensure quality labeling;

Basic purpose:

It can be used for a variety of cylindrical objects, small taper round bottle full roll or half roll, front and back double

standard labeling, such as food cans, cosmetics round bottles, medicine bottles; Can match with ribbon coder,

therefore it can print production date.

Machine structure introduction:

1, Part of labeling head

Using 20mm thick aluminum alloy plate , The whole process of grinding,ensure that plane grinding

surface smoothness.The surface of aluminum alloy anode processing, gush arenaceous

technology, ensure hardness and beautiful.

All feeding label guide bar use heavy whole process, for making sure every guide bar with the vertical

degree, ensure feeding label is stability.

Head motherboard adopt the most advanced CNC processing center production, to ensure that each size precision.

before and after adjustment for direction, suitable for various products, various position labeling.

Adopt Japanese Mitsubishi PLC control system,a more stable performance

Machine case use 304 SS the whole seal structure, effective to prevent rust and water into.

Guanzhou