——Realize the intelligent - continuous - high - efficiency of enterprise production——

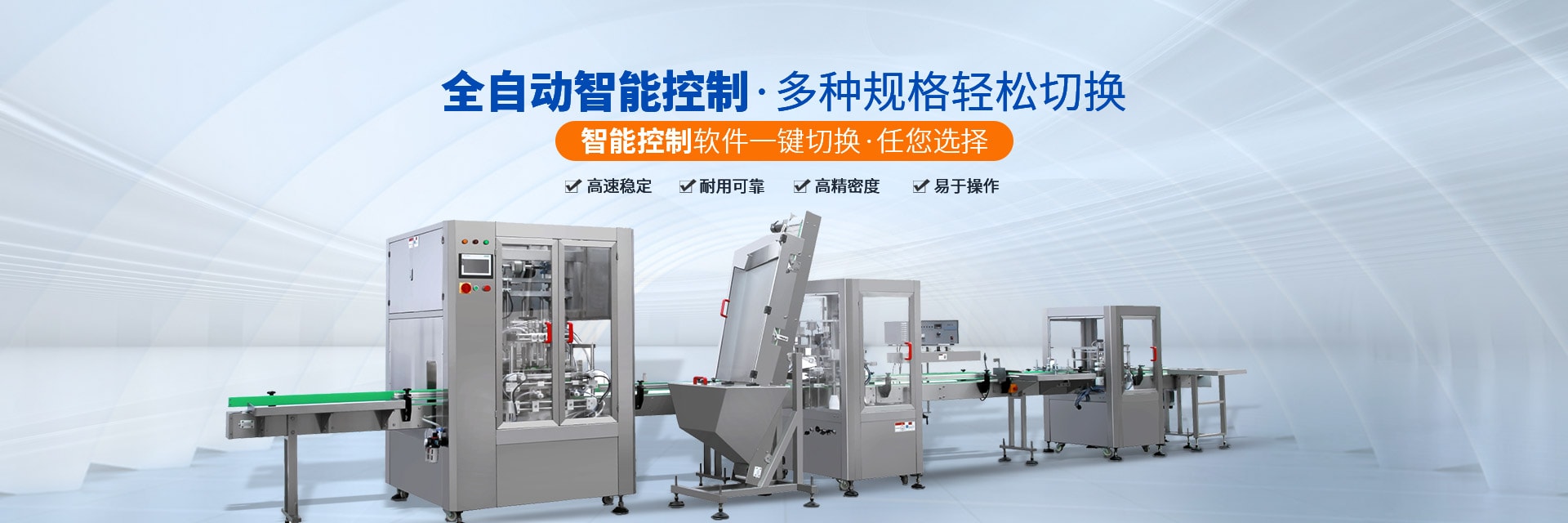

Automatic filling (liquid) production line

Features:

The production line is suitable for filling low viscosity grainless liquid, and the filling volume can be adjusted in a big scope. Dip-type filling can be chosen, which neither generates foam easily and nor splashes during filling. The indicator for lack of material is available. The production line is controlled by microcomputer (PLC) procedure, which facilitates convenient, reliable and simple operation. Japanese SUNX infrared sensor is used for position control to ensure precise position. The imported magnetic gear pump is adopted for filling, ensuring high filling precision. The housing is made of 304# corrosion resisting stainless steel, which conforms to GMP standard and makes cleaning easy. The machine enjoys wide application in food, pharmaceutical and cosmetic enterprises.

Technical parameter:

Filling volume 5~500 (ml)(The filling volume can be set, and the molds should be changed for bottles of different specifications.)

Filling form magnetic gear pump filling

Filling speed 20~25 bottles/min 180ML

Filling precision ≤ ±1%

Conveying speed 5~10m/min

Total power 1.2KW/220V AC three-phase four wire

Mode of cap feeding vibrating type

Protective device indicator for lack of material in vibrating plate, indicator for lack of material in trough and stop of screwing

Air supply 0.5-0.8MPa

(It can design according to client's requirment!)