——Realize the intelligent - continuous - high - efficiency of enterprise production——

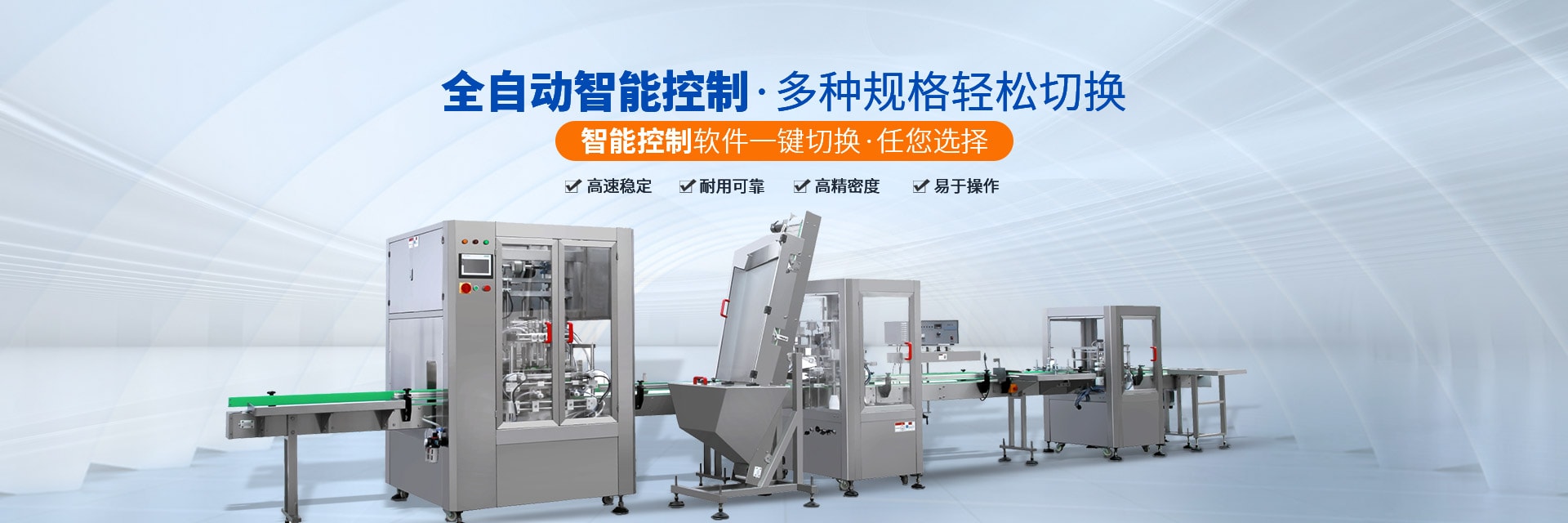

Automatic filling (glue) production line

Introuduce

The production line is suitable for filling low viscosity grainless liquid, and the filling volume can be adjusted in a big scope. The position can be adjusted to adapt to containers of various volume and shapes. Dip-type filling can be chosen, which neither generates foam easily and nor splashes during filling. Mouth filling proximity warning is also available. The production line adopts Chinese English man-machine touch screen and microcomputer (PLC) procedure control. 50 groups of memory are available, which makes change of different specifications of products simple and convenient. The start/close and flow of each filling mouth is controlled in a human-friendly way. The cap screwing machine adopts intelligent mode of screwing, i.e. the cap can be tightened without being damaged. Japanese SUNX infrared sensor is used for position control to ensure precise position. Variable-frequency speed-control ensures uniform conveying speed. The housing is made of 304# corrosion resisting stainless steel, which conforms to GMP standard and makes

Technical parameters

Filling volume 5~500ml (self-flow multiple-head dip type)

Filling speed 30~80 bottles/min (50~200ML)

Filling precision ≤ ±1%

Conveying speed 5~10m/min (variable-frequency speed control)

Total power 1300W/220V AC single-phase

Protective devices mouth filling proximity warning, lack of cap in vibrating plate, warning of lack of liquid in reserve tank

Speed of screwing 80~135 bottles/min (variable-frequency speed control)

Mode of cap feeding vibrating type

Air source air displacement ≥50 L/min (pressure ≥0.6MPa)

(It can design according to client's requirment!)