——Realize the intelligent - continuous - high - efficiency of enterprise production——

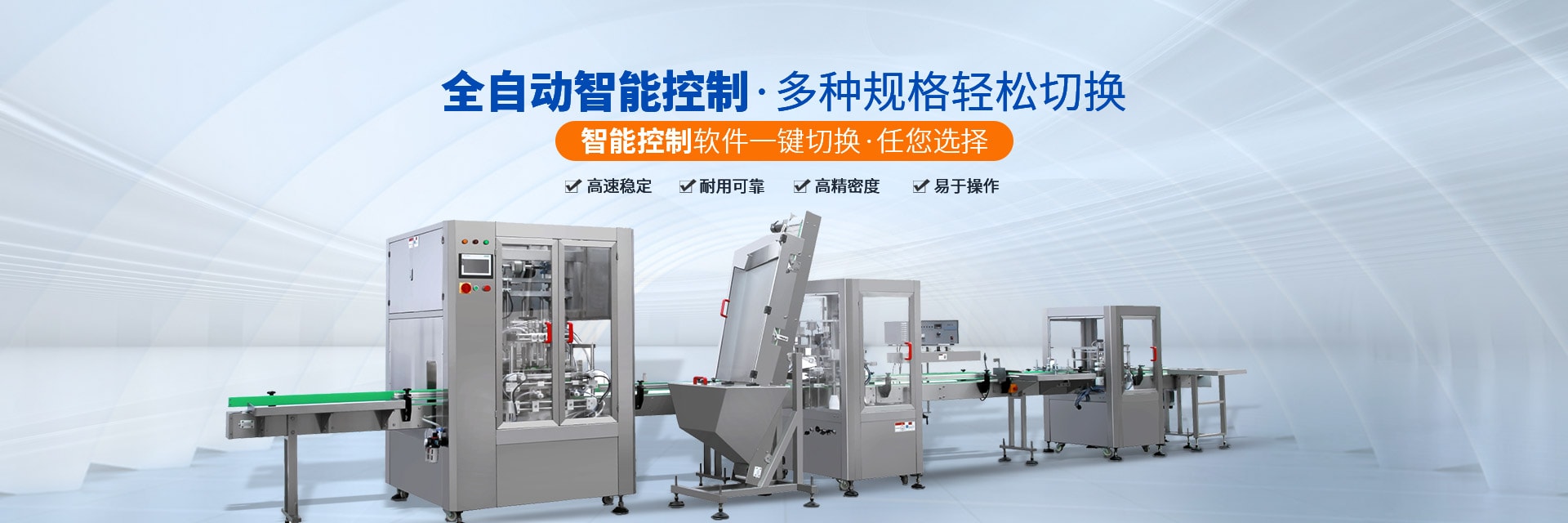

Washing and filling production line

Product name: Washing and filling production line

Introduction:

Bottle filling production line composite by high-pressure cleaning machines and two filling machines and turntable composition, high-pressure washing Chit machines, mainly for bottle washing, using a fixed spray nozzle, fixed-nozzle tubular nozzle, the next warehouse for unloading tank, wastewater tank to exclude, the cleaning warehouse exterior plexiglass shield. Stainless steel sticks of intermediate care delivery and positioning of bottles, different bottle shape change within the core. Cleaning warehouse into the bottle with push chuck bottles. Clean stainless steel jet pump self-priming pump, head 25 m, flow rate 2.4 cubic meters / hour.

Technical parameter:

high-pressure cleaning machines (clean bottle body)

Machine length entrance length 1.4m, clean machine length 0.3m, clearance from the floor 75cm

Washing speed 600-1200 bottles/min

Wash material wine, aseptic compressor air

2 heads filling machine

Filling machine heads number 2

Filling volume 100-500ml

Filling type self-flowing filling

Filling speed 600-1200 bottles/hour

Filling error ±1%

Air pressure 0.5-0.8MPa

(It can design according to client's requirement!)