——Realize the intelligent - continuous - high - efficiency of enterprise production——

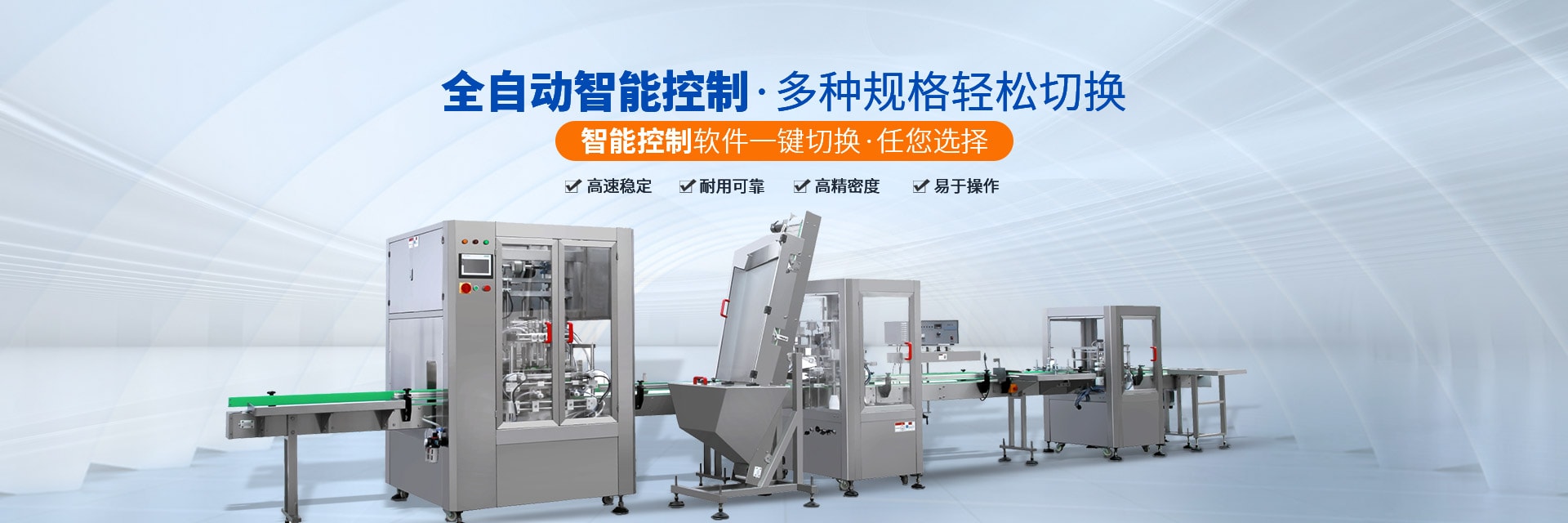

Product:Automatic filling & capping & sealing machine:

Technical parameters:

|

Number of filling head |

2 |

|

Induction head number |

1 |

|

Capping head number |

1 |

|

Applicable scope |

Different bottle type need to change according to the mould |

|

Filling volume |

100~1000(ml) |

|

Filling form |

piston-type filling |

|

product filling speed |

10-20 bottles/min |

|

Filling precision |

±1%(According to the material concentration viscosity character is different, filling different quantity, speed and different) |

|

materials |

Filling rack with 304 stainless steel, contact content of the 304 stainless steel or engineering plastic |

|

Chuck speed |

3-15meters/min |

|

Chuck diameter |

800mm |

|

Chuck material |

pom |

|

Conveying speed |

5-15m/min |

|

Ground clearance of line surface |

75mm±50mm |

|

Total power |

2.5kw/220v AC single-phase |

|

Procedure control |

Taiwan Taida imported PLC and touch screen man-machine interface |

|

|

0.5-0.8MPa |

|

Molds material |

pom |

|

Driving motor |

370wTaiwan speed-regulate of explosion-proof electric motor driver |

|

Material capacity |

20L |

(The above parameters is for standard machine, other requirement, we can design according to your needs.)