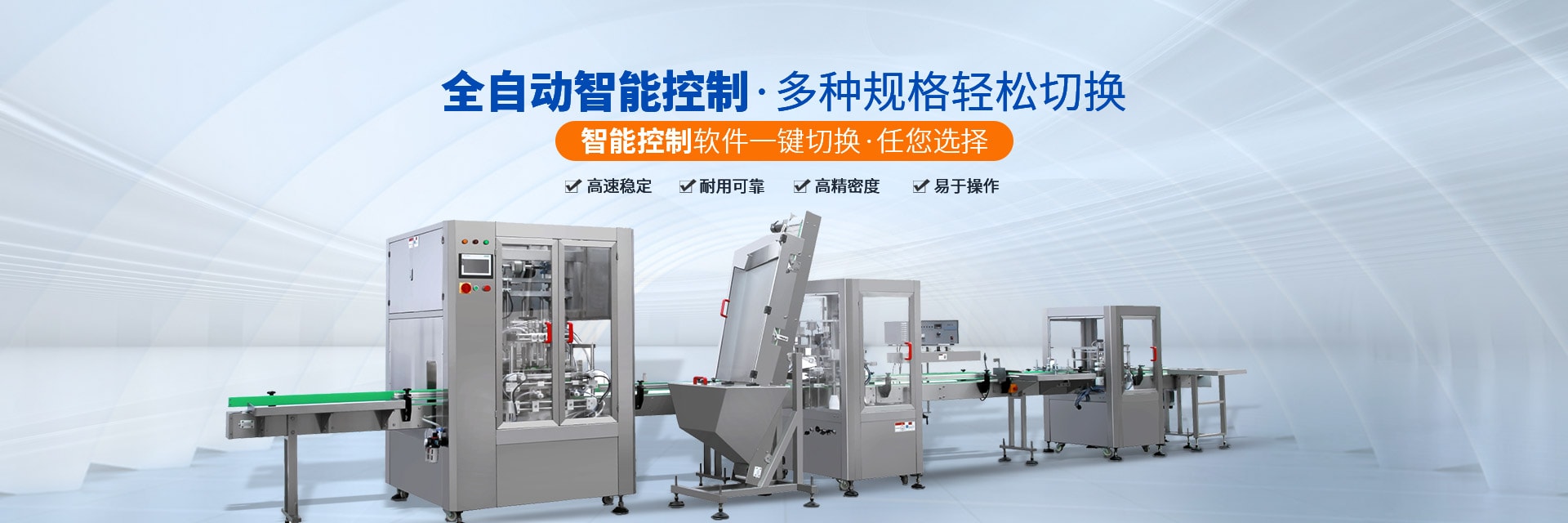

——Realize the intelligent - continuous - high - efficiency of enterprise production——

Product introduction:

Tomato jam production line is mainly made up of 10-heads filling , straight-type capping machine, vertical round filling machine ,send bottle turntable .import PLC procedure to control,filing mouth and feeder material and contact liquid parts are 304 stainless steel ,sealing ring is adapt PTFE.

This machine is used in the food, pharmaceutical, cosmetic, chemical industry and paste filling of the special business .

Technical parameters:

Filling heads number:10

Filling volume: 0.1L -0.5L

Filling form;piston-type filing

Filling speed:50-60bottle/hour(450mm)

Filling error: ±1%

Air pressure :0.5-0.8mpa

Conveyor belt :82mm POM chain type

Driving motor :550w inverter speed governing motor

Power: 1KW /380V three phases five line power

Straight line type under cap machine

Diameter of cap:50-60mm

Under cap speed:50-60 bottles/min

Capping form:magnetism conveyor belt send cap and capping

Straight line type capping machine

Width of the bottle : 40-90 mm

Diameter of the capping :30-60 mm

Production capacity:50-60 bottles/min

Capping motor :550w

Vertical round labeling machine

Labeling error :±1 mm

Range of labeling :H:10-100mm L:10-300mm

Production capacity:60-150 bottles/min(can do according to diameter of the bottle)

Rated voltage :220v/50hz

Total power:500w

Dimensions :1710×950×300(mm)(L×W×H)

Total weight : 146 KG

(It can design according to client's requirement)