——Realize the intelligent - continuous - high - efficiency of enterprise production——

Guangzhou Guanhao automatic coating material filling machine that we produce adopts pneumatic filling. It is with high measurement precision and will not be effected by materials. From the different nature of the materials, it can be divided into ordinary type, EXA type, DWK-F and so on. From the different ways of filling, it can be divided into standard type, hopper type, bottom irrigation type and so on. The irrigation nozzle has three types: submerge, splash proof and prevent drawing. Filling range is from 10ml to 10L. It is widely used in the quantitative filling of chemical, oil, asphalt, glue, lubricating grease, coating, paint, ink, jam, sweet sauce, egg, food additives and other kinds of liquid and fluid materials.

Basic structures:

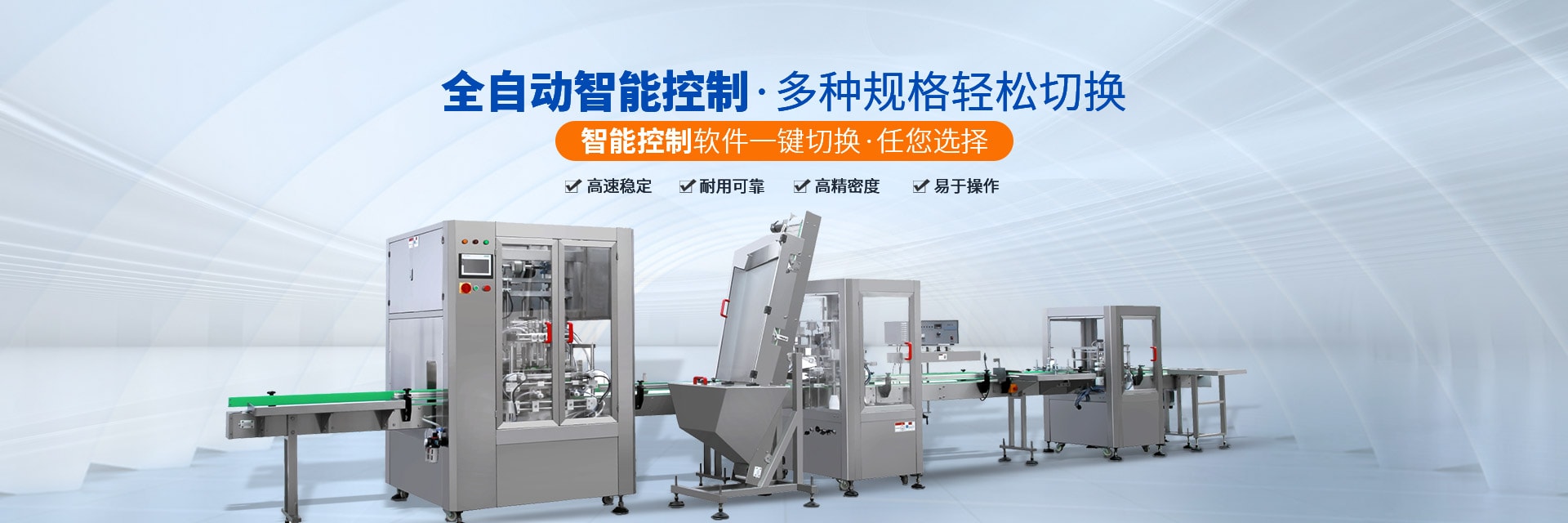

The paint filling machine consists of feeding system, weighing filling system, stainless roller system, rack, pneumatic control, electrical control and other systems.

The weighing system consists of weighing support, sensor, weighing platform. The feeding valve consists of two filling valves (Fast Fill and Slow Fill) which not only can speed up filling speed but also filling accuracy. In the adjustment range of the filling quantity, you can set the filling weight and other weight parameters willfully.

The irrigation nozzle part is made of SUS304 or SUS316L stainless steel. It has strong corrosion resistance.

The weighing platform connects with the rack through sensor.