——Realize the intelligent - continuous - high - efficiency of enterprise production——

Apply to unstable circular cylindrical objects, half the circumference of the labeling, adopts horizontal transmission, horizontal sides labeling method, increase the stability, improved labeling efficiency.

Optional code printer or to spurt the code machine labeling, which can realize on the label print production date, batch number and jet printing bar code and other information.

Optional to spurt the code machine conveyor belt, and can realize labeling before or after the labeling on the product production date, batch number, bar code and other information

________________________________________

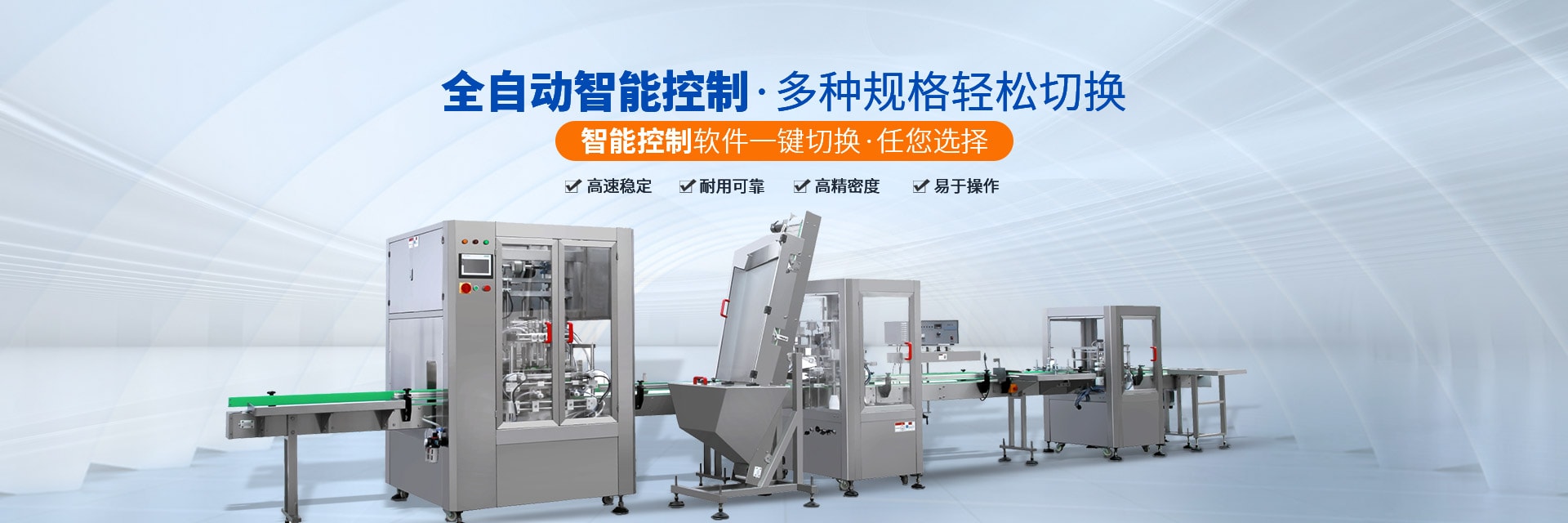

Product picture

Working principle

* core working principle: round bottle wheel separate products, send it on the conveyor belt, sensors detect the product after, back to the signal to the labeling control system, in the appropriate position control system control corresponding motor send labels and attached with a stay in product labeling position, product flows through the device, the belt drive Product, label roll cladding, a label attached.

*operation: put a product (on blanking box) - > separate product and spread to the conveyor chain roller intermediate - > product delivery - > product testing - > label - > - > collection were post logo products.

________________________________________

Applicable scope

* Applicable label: the adhesive sticker label, adhesive sticker film, electronic supervision code, bar code, etc.

* Applicable products: labeling circumferential surface or small conical surface attached with a tag or membrane of small products.

* Application industry: widely used in medicine, cosmetics, electronics, metal, plastic and other industries.

Application example: solid glue bottle labeling, oral liquid bottle labeling, labeling, lipstick pen labeling, etc.

________________________________________

Product feature

* High speed, USES the side horizontal roller conveying mechanism, conveyor chain slope, automatic guide is the bottle, stable conveying label. Up to 400 bottles/labeling speed Minutes, save a lot of manpower material resources;

* Bottle broken rate is very low, dividing technology and the flexible application of flexible standard technology, bottle labeling smooth, broken rate is less than one over one hundred thousand bottle;

* Labeling quality, USES the belt around technology, head and tail to stick label high contact ratio;Rub roll cladding, labeling smooth, no wrinkles, no gas Bubble, improving the quality of packaging;* high stability, Siemens PLC + Germany's Siemens touch screen is easy to measure label advanced electronic control system of electric eye, support equipment 7 x 24 hour high-speed operation;

* Intelligent control, automatic photoelectric tracking, have any label, there is no standard automatic correction and label automatic detection function, prevent leakage and labels to waste;

* Strong health, mainly adopts stainless steel and advanced aluminum alloy manufacturing, in line with the GMP production standards, firm structure, beautiful and easy;

* Have the function of fault alarm, production count function, power saving function, set number production function, parameter setting protection function, convenient production and management;* Optional features:

(1) Hot code/printing function;

(2) Automatic discharging function (consider) combined with products;

(3) Automatic feeding function (according to the requirements of client).

________________________________________

Technical parameters

The following technical parameters of standard model machine, other special requirement and function, can be customized

◆applicable label length(mm):20mm~100mm

◆applicable length width(paper backing width/mm):20mm~130mm

◆applicable product diameter(for round bottle):external diameter: φ10mm~30mm

◆applicable label external diameter(mm):φ280mm

◆applicable inner diameter(mm):φ76mm

◆labeling accuracy(mm):±0.5mm(exclude packaging and label error)

◆label sending speed(m/min):BUJIN:5~19m/min servo:5~25m/min

◆labeling machine(pcs/min) :BUJIN:100~250pcs/min servo:150~400pcs/min

◆ sending speed(pcs/min):450pcs/min

◆ weight(kg):about 200kg

◆ frequency(HZ):50HZ

◆ voltage(V):220V

◆ power(W):1020W(BUJIN) 1470W(servo)

◆equipment external dimension(mm)(L×W×H):2050mm×650mm×1450mm。