Round bottle positioning labeling machine

Round bottle positioning labeling machine

Round bottle positioning labeling machine

Basic application:

Applicable for circumferential surface labeling bottles of class object, can stick a single standard and double standard, is double the distance between flexible adjustment, such as gel water round bottles, food cans such as labeling, widely used in cosmetics, food, medicine, disinfectant, etc. Equipped with circumferential position detection device, which can realize location specified in the circular surface labeling. Optional ribbon printer and spurt the code machine, production date and batch number printed on the label information, integrates label - code.

________________________________________

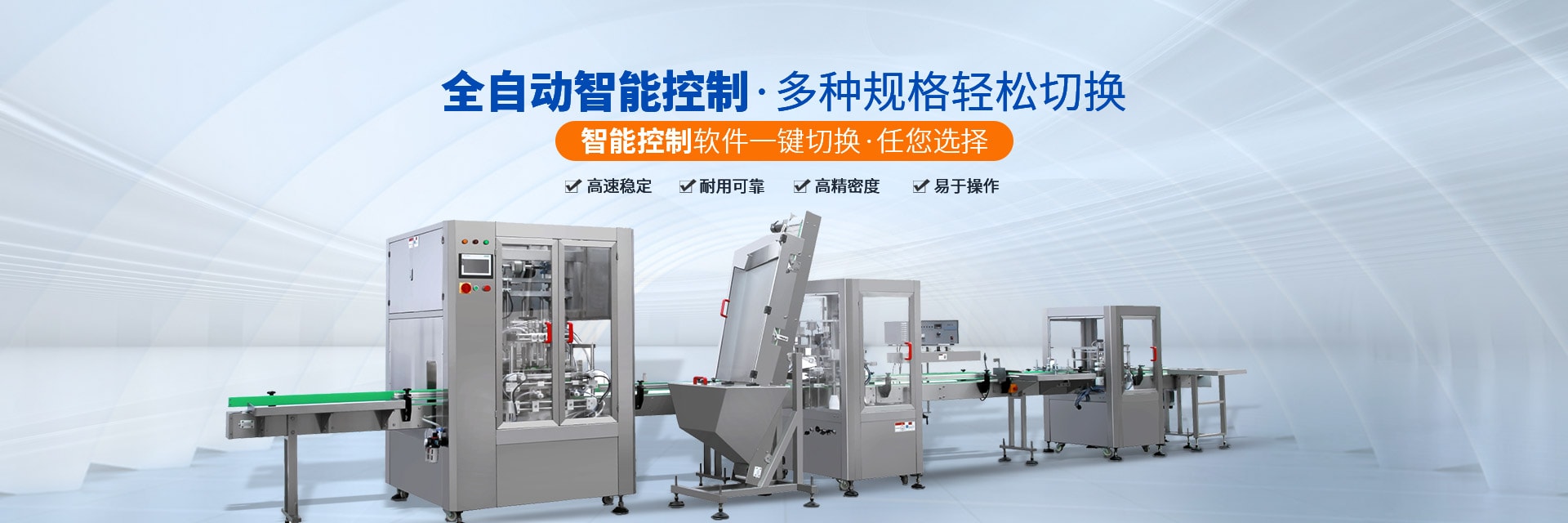

Product picture

Working principle

* Core principle: put the product to the conveyor belt, into the bottle body, bottle dividing mechanism separate products, sensors detect the product after, back to the signal to the labeling control system, in the appropriate position control system control corresponding motor send labels and attached with a stay in product labeling position, at the same time scale, a label attached.

* Operation: put the product conveyor belt (line) - > product delivery - > product separation - > product testing - > product positioning - > labeling and standard - > collection were post standard products.

________________________________________

Applicable scope

* Applicable label: the adhesive label, adhesive sticker film, electronic supervision code, bar code, etc.

* Applicable products: between 30 mm to 90 mm diameter round bottles.

* Application industry: widely used in medicine, food, toys, cosmetic, etc.

* Application example: disinfection bottle labeling double labeling standards, gel water, a wine bottle is calibration label, etc.

________________________________________

Product feature:

* Powerful, the same device can realize round bottle of class object single standard labeling and double marking label, double spacing can be flexibly adjusted. Equipped with circumferential position detection device can be realized in the circumferential surface positioning labeling functions; Coping mechanism

* Label high contact ratio, configuration, in combination with 3 axis positioning, put an end to the bottle fluctuate, improve the labeling accuracy;

* Automatic bottle, the bottle mechanism with snap type, effectively eliminate the bottle itself error caused by the bottle is not smooth, improve stability.

* Touch screen control, human-computer interaction interface with operation teaching function, parameter modification straightforward, all kinds of switch function is simple;

* Intelligent control, automatic photoelectric tracking, have any label, there is no standard automatic correction and label automatic detection function, avoid the waste of label and leakage;

* Strong health, mainly made of stainless steel and advanced aluminum alloy quality, in line with the GMP production requirements;

* Automatic stop function, production count function, power saving function (production set period of time, the device automatically to the standby mode to save power),Set number production function, the parameter setting protection function (parameter setting rights management), convenient production and management;