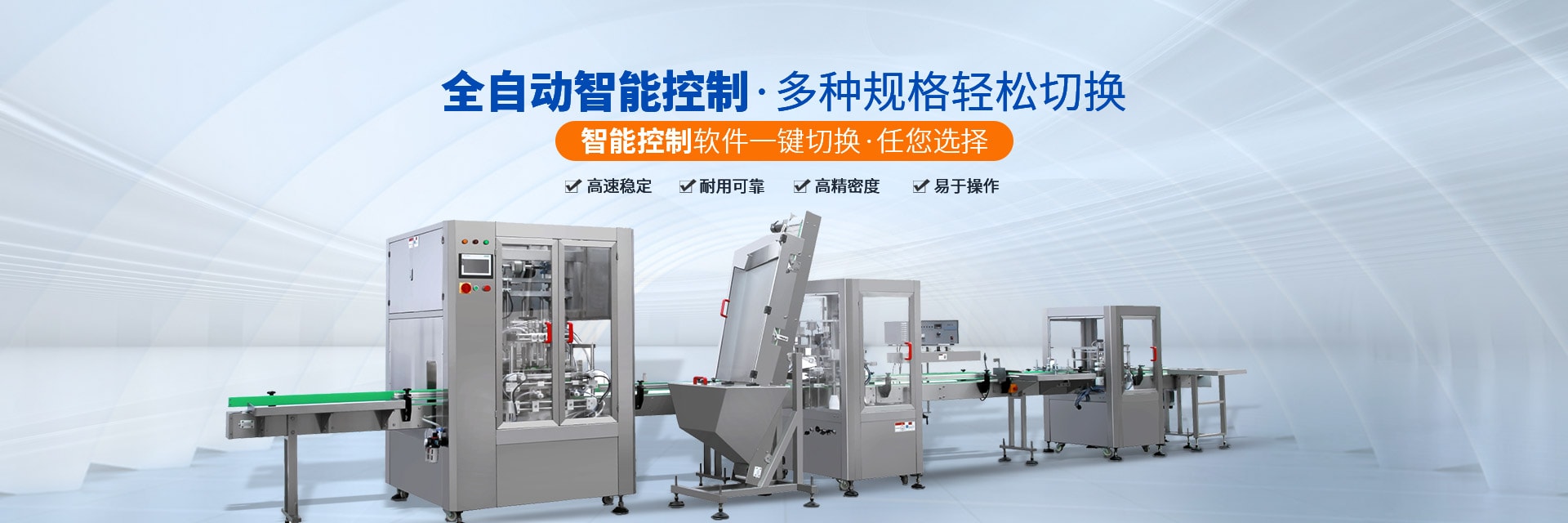

——Realize the intelligent - continuous - high - efficiency of enterprise production——

introduction :

meat jar production line is made of 6 heads filling machine ,automatic to put down the caps ,press capping machine ,foil AL sealing machine ,shrinking machine .

technology parameters :

quantity of the filling heads : 6

volume : 100-1000 ml

filling form : piston quantitative type filling

filling speed : 2500 bottles / hours ( 100ml)

error : ±1%

air press : 0.5-0.8MPa

conveyor belt : 82 mm pom chain

drive motor : 550 w inverter adjust-speed motor

automatic down over machine technology parameters :

diameter of bottle body : 60-100 mm

diameter of the cap : 65-100 mm

speed : 30-40 pcs /min

arrange cap power : 140 w

capping machine technology parameters :

diameter of bottle body : 30-100 mm

diameter of the cap : 30-50 mm

speed : 30-40 pcs /min

motor : 90 w

Aluminum foil induction sealing machine technical parameters :

diameter of the bottle mouth : 30-120 mm

height of bottle : 50-300 mm

capacity : 30-40 bottles / hour

conveyor belt : L: 1700 mm , W : 82 mm

conveyor belt speed : 0-13.5 m /min

voltage : 220V/50Hz

power : 4000 w

size : L 1700× W 410×H 1350mm

weight : 180 kg

100/350 bottle mouth shrinking machine technology :

powwer : 6 kw ,220 v

fever pipe :900 w ,6 pcs

temperature : 180 ℃ (adjust )

speed : 1-10 m /min (adjust )

conveyor belt : W :82 CM ,Length of the fever pipe : 1.2 m ,H : 10-35 CM (adjust )

size : total length :3.53 m,enter part : 1.8 m ,export :0.53 m ,W :0.3 M ,H: 75 CM

( IT can design according to the client's need )